What are gas springs?

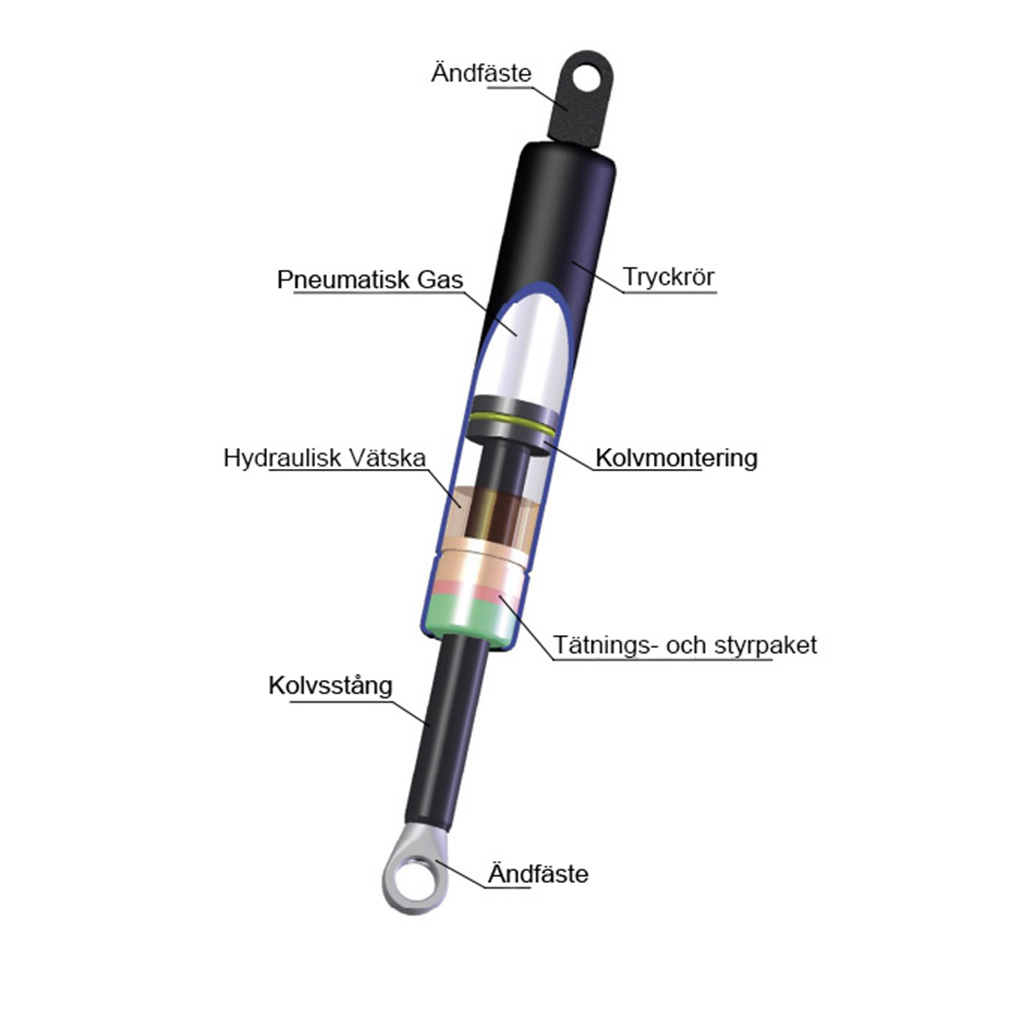

Gas springs are a type of spring mechanism that uses compressed gas, usually nitrogen, to exert force. They consist of a cylinder and a piston rod and are used to control the movement of a load by damping and braking the movement.

How do they work?

When the piston rod is pushed into the cylinder, the gas is compressed, creating a back pressure. This back pressure is what provides the force to either lift or hold a load. When the piston rod is pulled out, the gas expands and allows movement.

Applications

Gas springs are used in a variety of applications, including: • Vehicle tailgates and engine hoods • Office chairs • Machinery and industrial equipment • Furniture and home decor

FlexFill™ - Real Flexibility

With Aero Materiel’s FlexFill™ service, you get gas springs where the pressure is adapted to your application and your customers’ requirements. The gas springs can be ordered with different forces from 50 N up to 2000 N in different variants depending on the type of hatch they are to be adapted to. FlexFill™ is designed to be easy and affordable to order even a smaller number of gas springs, with the pressure you desire.

Benefits of FlexFill™

Delivery within 48h directly from Jönköping • Opportunity to get the gas springs with your own printed label • Flexible products and competitive prices by stocking basic variants and adjusting the force • Quick and easy access to prototypes for testing and development needs Benefits of gas springs • Smooth and controlled movement • Long lifespan and maintenance-free • Can be adapted for different force and speed

Maintenance and safety

Gas springs require little maintenance, but it is important to regularly check them for leaks and damage. Never use a gas spring that is damaged, as it can lead to accidents and injuries. Hope this helps you understand the basics of how gas springs work and their applications. If you need more detailed information or help with something specific, don’t hesitate to ask!